-

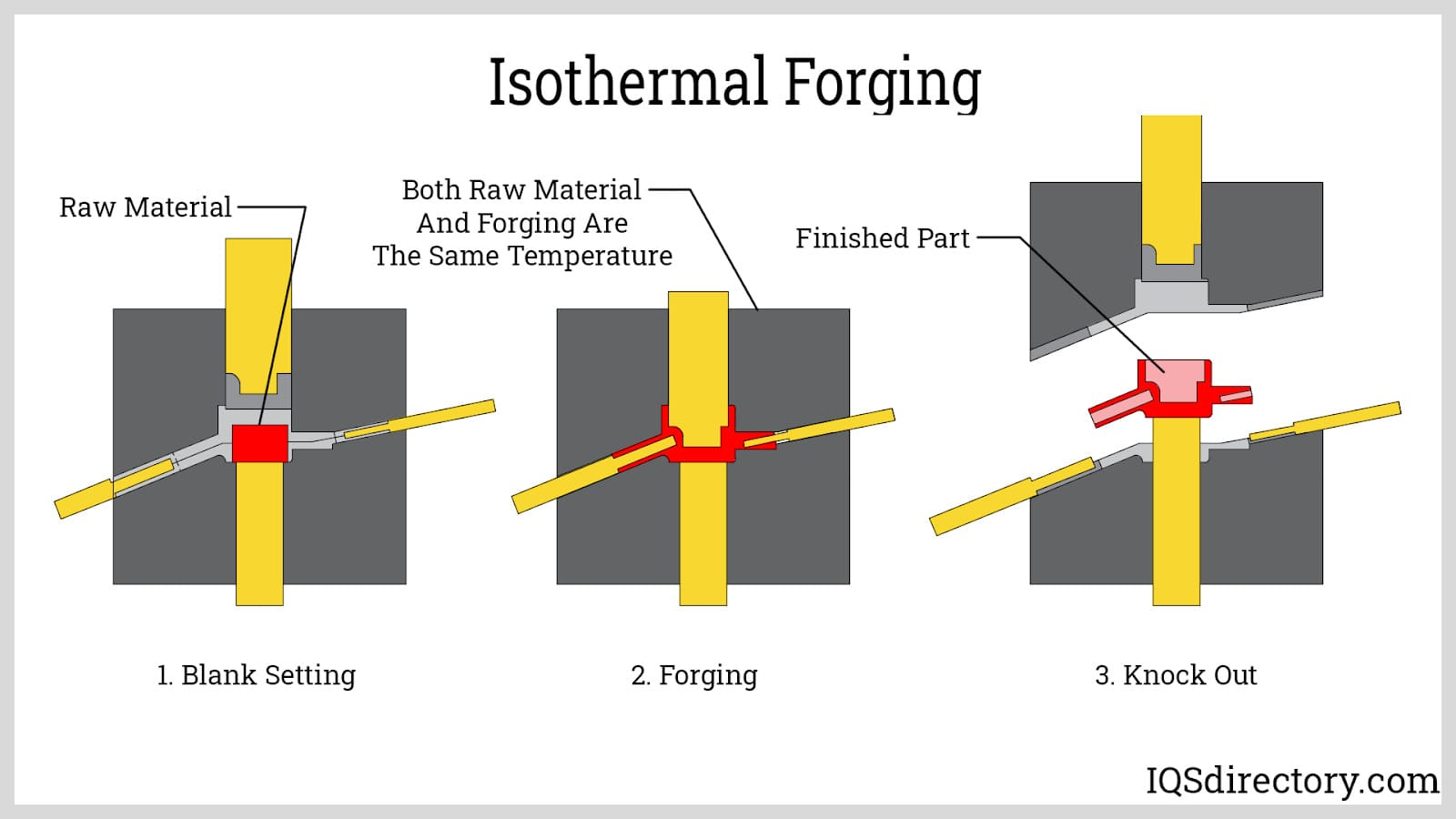

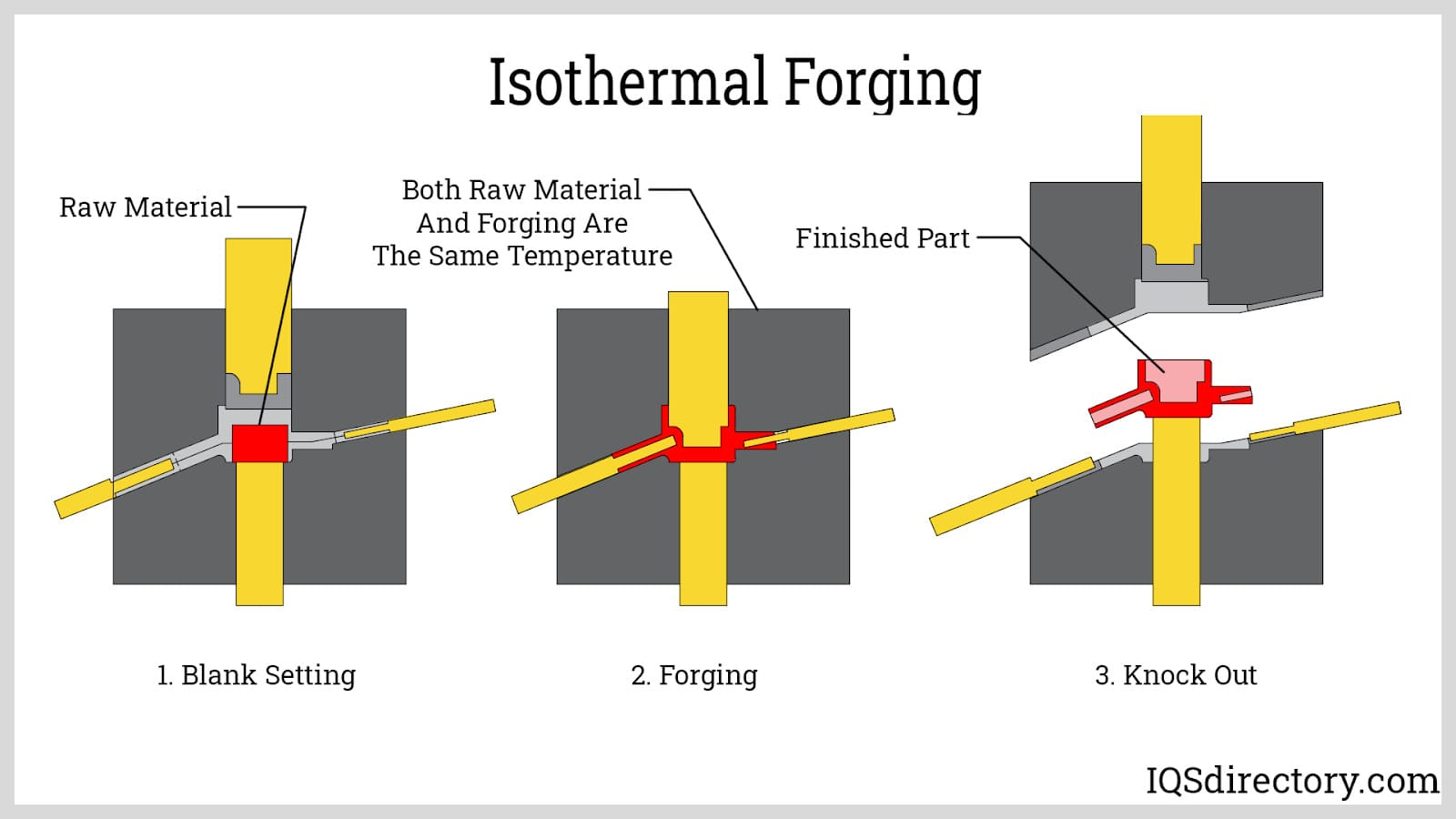

What is the difference between hot die forging and isothermal forging?

Hot die forging and isothermal forging are commonly used metal processing methods in modern industrial production, especially in the field of aerospace engines. The emergence of hot die forging and isothermal forging allows metals to maintain excellent processing performance and mechanical proper...Read more -

What is the difference between Monel 400 and Monel 500?

When choosing the right alloy for your application, you want to choose one that meets your performance requirements and offers durability, strength and corrosion resistance. Two alloys that have proven popular among manufacturers and engineers are Monel 400 and Monel 500. Both copper-nickel alloy...Read more -

What is the difference between Monel 400 and Super Duplex Steel?

When it comes to choosing the right materials for your project, you’re often torn between two high-quality options. Monel 400 and Super Duplex steels are both popular choices with excellent properties. So, which material is better? This article will compare Monel 400 and super duplex steel ...Read more -

What is Hastelloy C-4?

Hastelloy C-4 (UNS N06455) is a nickel-based superalloy with excellent corrosion resistance and high temperature performance. This article will introduce in detail the chemical composition, production standards, corrosion resistance, high temperature resistance, typical application range, hot pro...Read more -

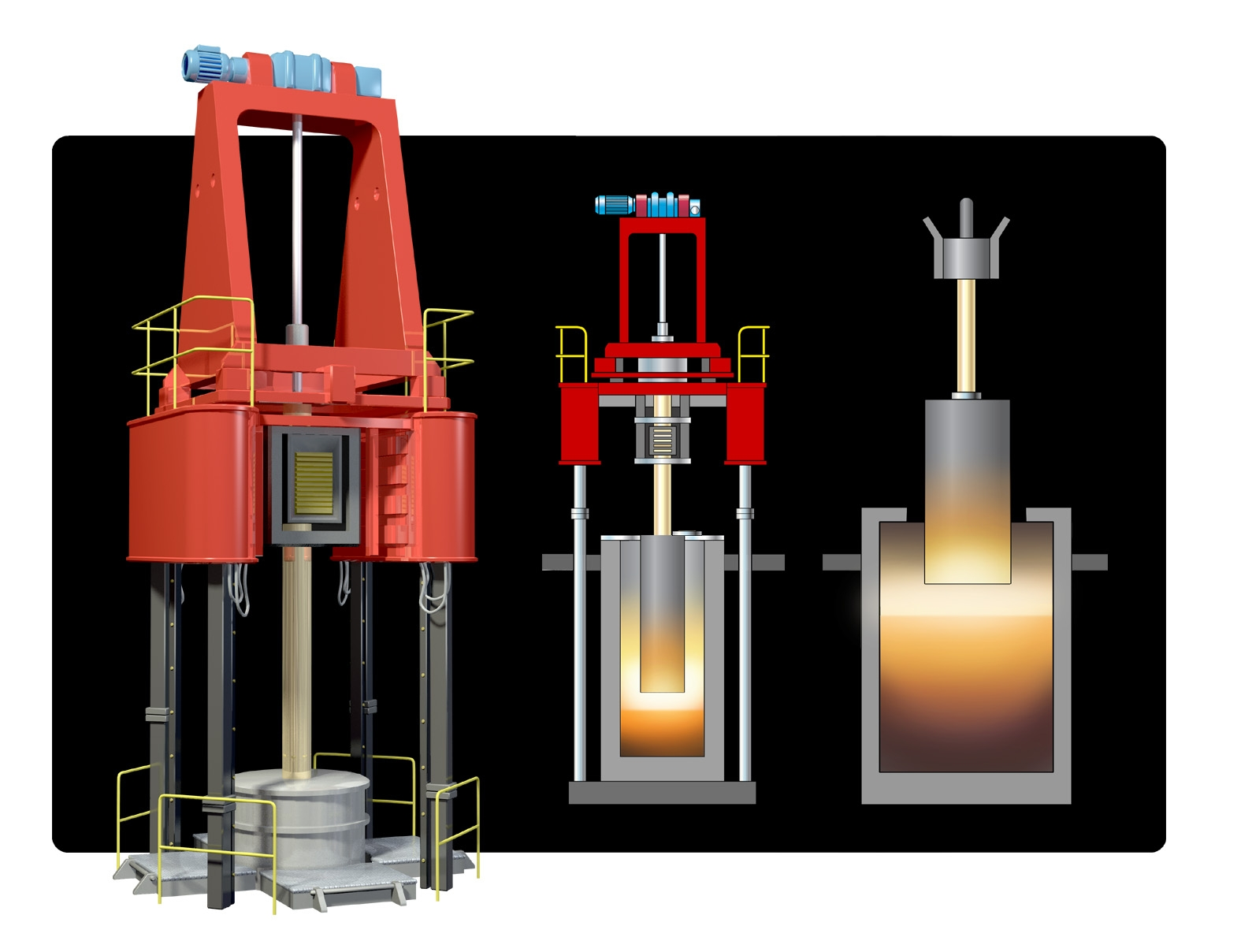

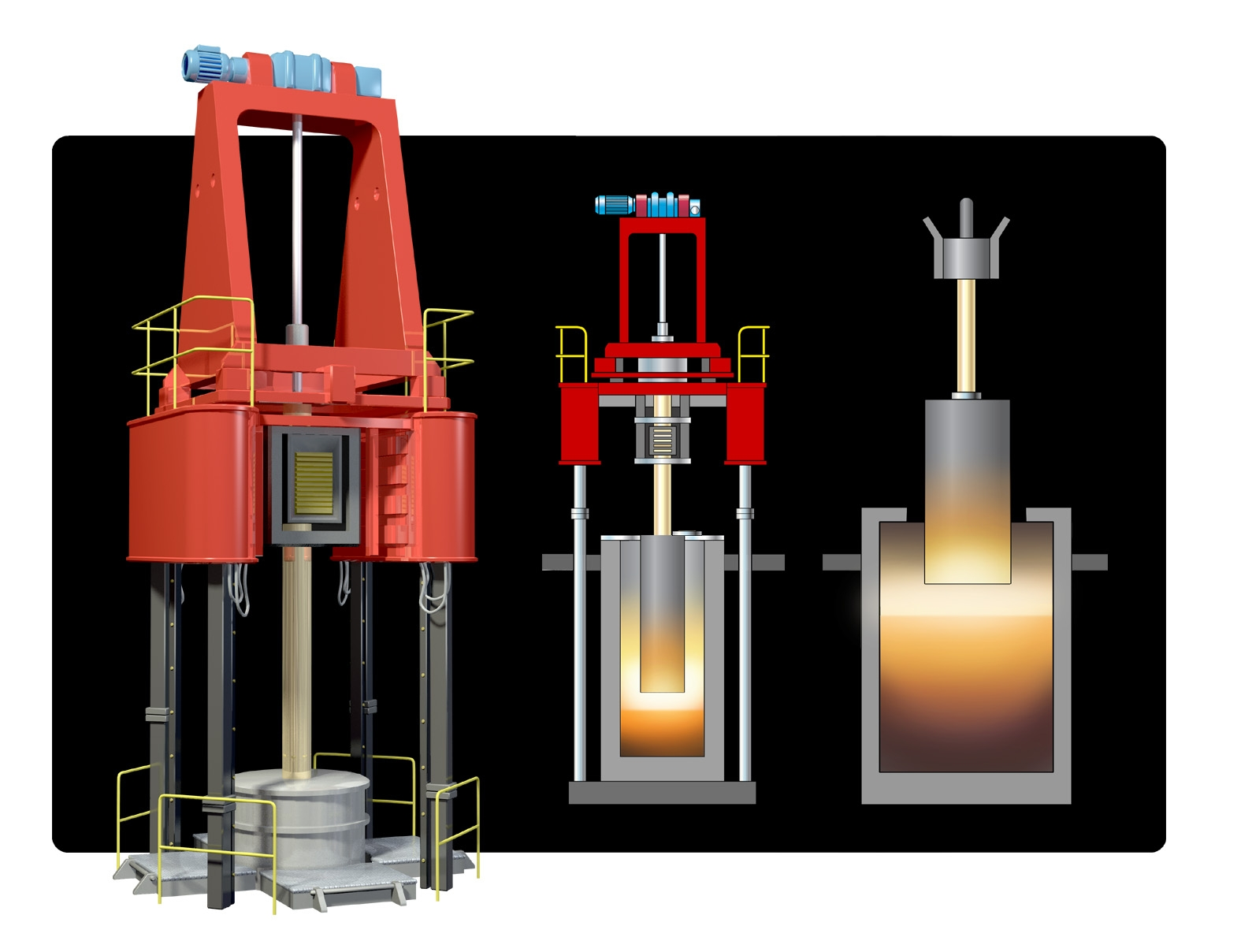

What is the ESR melting method?

Electroslag remelting is a steelmaking method that uses the resistance heat generated when an electric current is passed through molten slag to melt metal electrodes. In this process, the metal electrode is heated and melted, and falls in the form of droplets through the slag layer into the metal...Read more -

Monel 400 and super duplex steel – what is the difference?

Monel 400 and super duplex steel – what is the difference? When choosing the right material for a project, choosing between two high-quality options can be difficult. Monel 400 and Super Duplex steels offer excellent properties and are popular choices in various industries. But which one is...Read more -

Introduction and Application of Duplex Stainless Steel

Duplex stainless steel is a new star in stainless steel. Since the discovery of duplex structure in the 1920s, duplex stainless steel has developed for three generations. The first generation of duplex stainless steel is represented by AISI329 steel, which contains high chromium and molybdenum an...Read more -

High temperature alloys used in aerospace

High-temperature alloy is a primary metal material with iron, nickel, and cobalt as the basic elements and doped with various elements such as chromium, aluminum, titanium, tungsten, and molybdenum. It can work for a long time at temperatures above 600°C and under certain stress conditions. It ha...Read more -

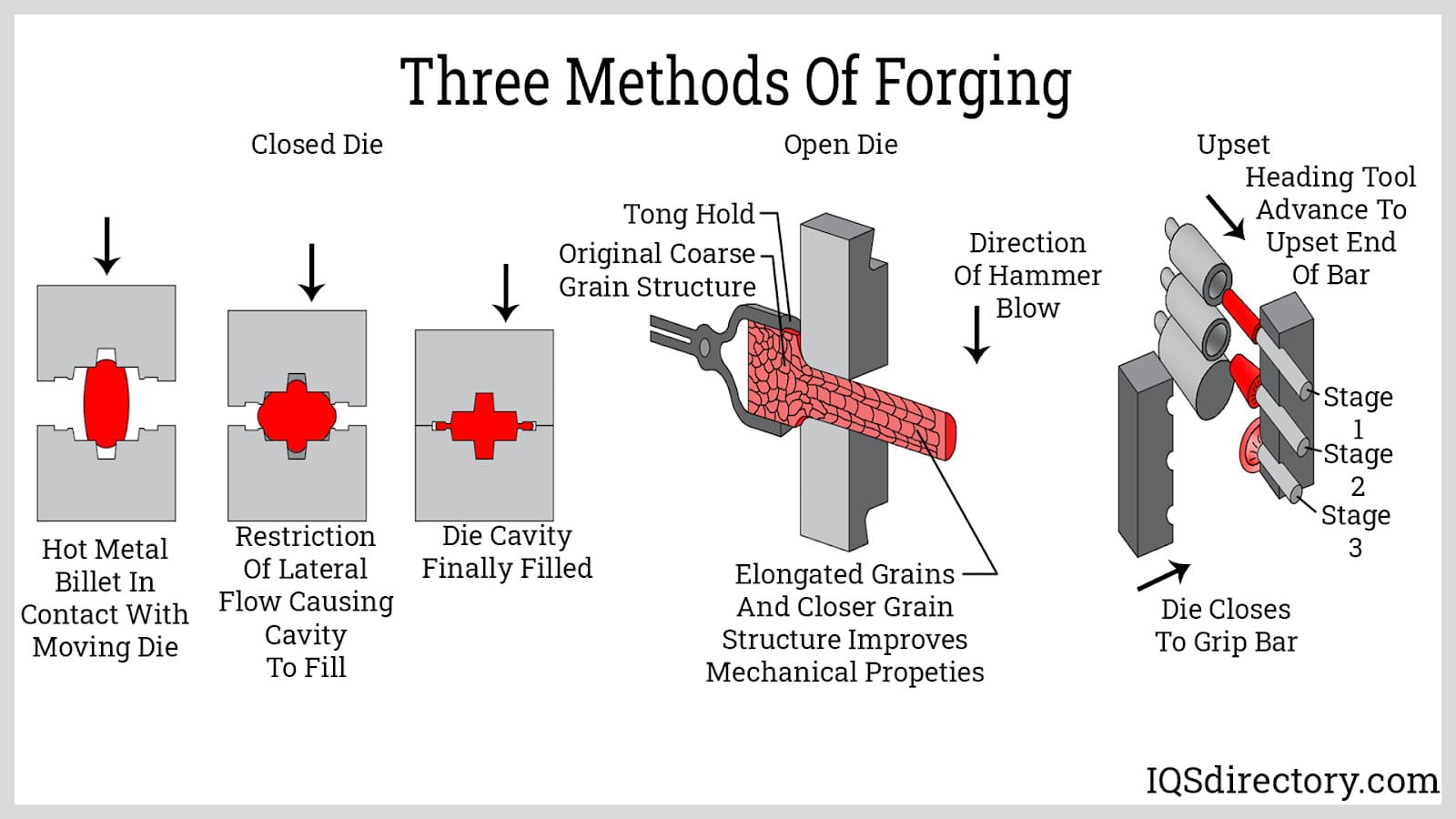

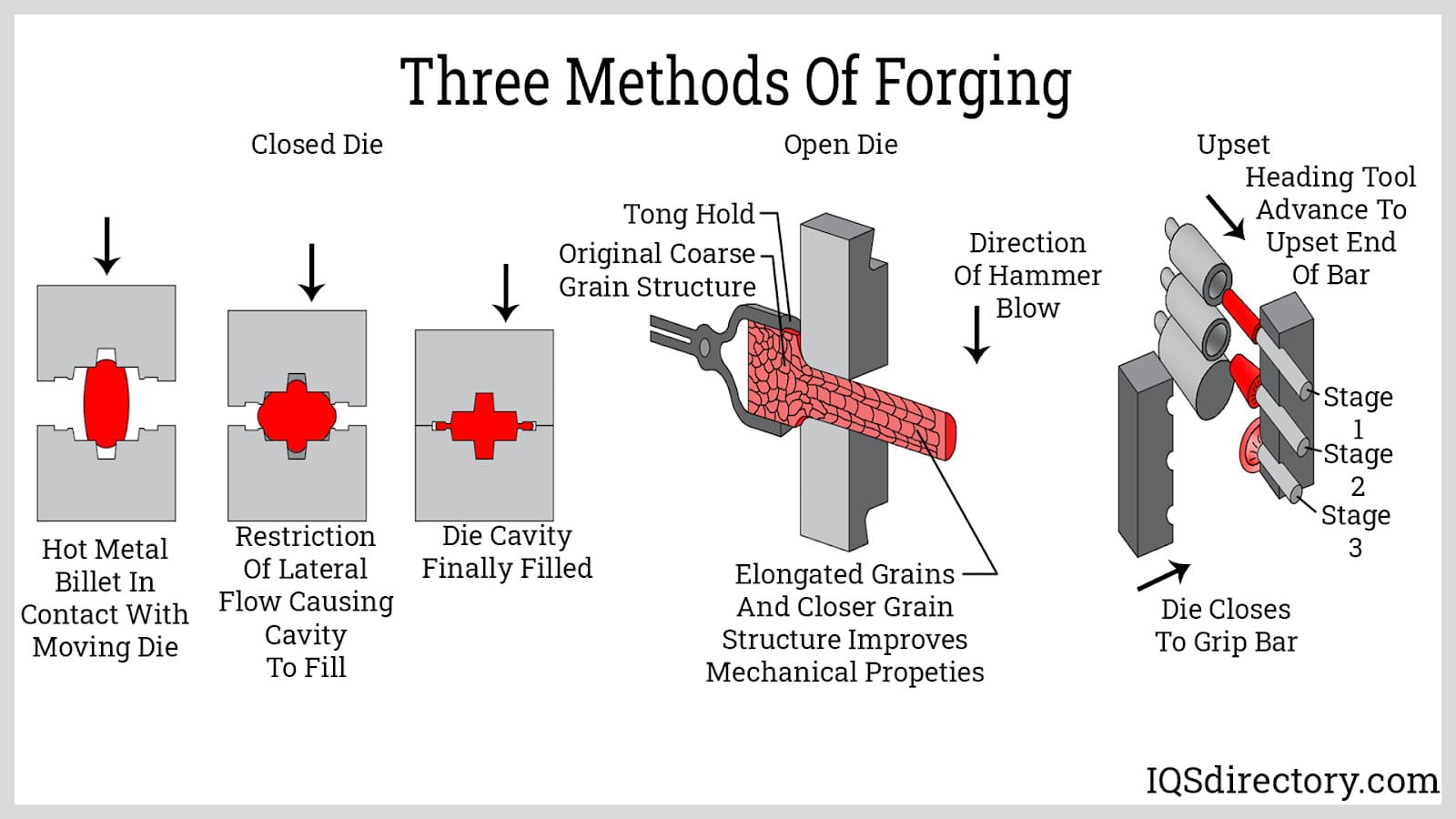

High temperature alloy forging method

High temperature alloys are a class of cutting-edge materials with high corrosion resistance, high temperature resistance and high temperature strength. According to the metal components contained in the alloy, high-temperature alloys can be divided into iron-based alloys and nickel-based alloys....Read more -

Application and design of Hastelloy in chemical equipment

With the development of the chemical industry, the materials of chemical equipment are also constantly updated. From the initial glass lining and resin lining to the current Hastelloy alloy, it is more and more widely used. When selecting materials for chemical equipment, we must not only conside...Read more -

Hastelloy C-276 welding precautions and techniques

Hastelloy C-276 is a nickel-based stainless steel with excellent corrosion resistance. It is widely used in various pipes, containers, heat exchangers, etc. in chemical equipment. Many techniques need to be paid attention to during the welding construction process to ensure that the welded parts ...Read more -

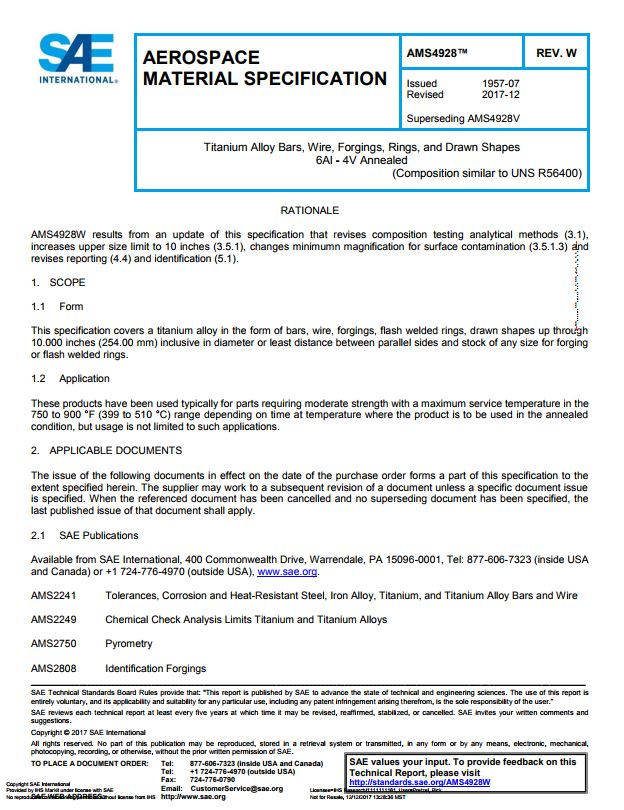

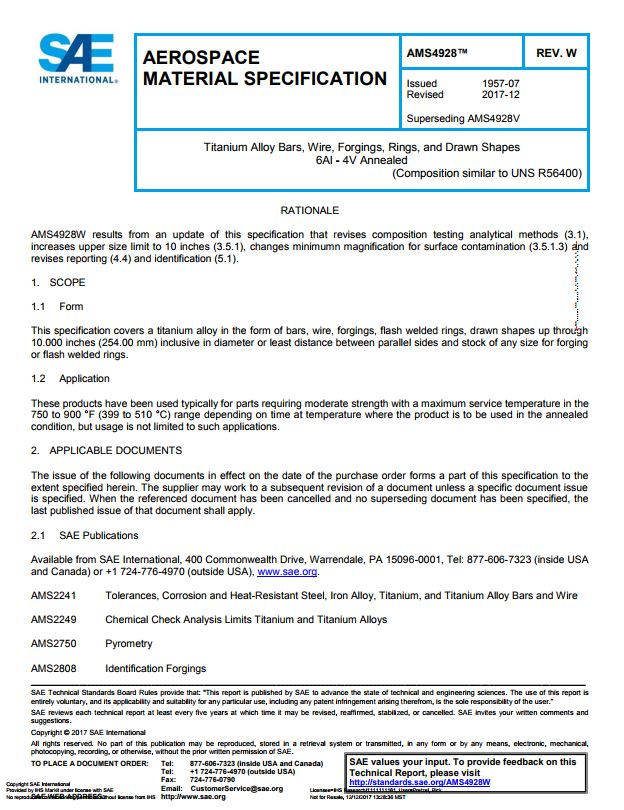

What is AMS4928?

Introduction: In the realm of aerospace engineering, the pursuit of lightweight yet robust materials has fueled advancements in aircraft design, fuel efficiency, and performance. Among these innovative materials, AMS4928, a titanium alloy, has emerged as a game-changer. In this article, we delve ...Read more