In the field of materials science, Inconel 718 and Inconel X-750 are both high-profile precipitation-strengthened superalloys. They are known for their exceptional high-temperature strength and corrosion resistance, which make them fundamentally different from solid solution alloys. However, when we tried to compare the two alloys, we found very few references. Therefore, this article will provide a detailed comparison of the history, chemical composition, and properties of these two alloys.

First, let’s take a look at the basic information about these two alloys. The UNS number for Inconel 718 is N07718, while the UNS number for Inconel X-750 is N07750. Both alloys were developed by US-based Specialty Metals, whose development history dates back to the 1950s and 1960s.

In terms of chemical composition, both Inconel 718 and Inconel X-750 contain large amounts of nickel, chromium and iron. However, Inconel 718 has stricter controls on harmful elements. In addition to sulfur, it also has strict limits on the content of manganese and phosphorus. This makes Inconel 718 far more durable at high temperatures than Inconel X-750.

Inconel 718 also outperforms Inconel X-750 in terms of corrosion resistance. This is mainly due to the fact that Inconel 718 contains more chromium, making it better than Inconel X-750 in terms of antioxidant properties. In addition, Inconel 718 also adds molybdenum element, which Inconel X-750 does not have. The addition of molybdenum makes Inconel 718 better resistant to pitting and crack corrosion.

In terms of high temperature strength, Inconel 718 is also superior to Inconel X-750. This is mainly due to two factors. First, Inconel 718 adds molybdenum, an ideal solid solution strengthening element that can increase the base strength of the alloy. Secondly, the precipitation strengthening phase of Inconel 718 is the γ” phase, while the precipitation strengthening phase of Inconel X-750 is the γ’ phase. The strengthening effect of the γ” phase is far greater than that of the γ’ phase, which makes the high temperature strength of Inconel 718 higher.

However, it is worth noting that although Inconel 718 has better high-temperature strength than Inconel X-750, its melting point is lower than Inconel X-750. This is because Inconel 718 has a higher iron content, which has a lower melting point than nickel.

In terms of application fields, Inconel 718 and Inconel X-750 have great overlap. They are both widely used in aerospace engine applications. However, because Inconel 718 has better corrosion resistance, it is more widely used in areas such as oil and gas, petroleum processing, and power generation.

In terms of price, although the Inconel 718 is better than the Inconel X-750 in most aspects, the price gap between the two is not huge. This is mainly because Inconel 718 has a lower nickel content and a higher iron content, which saves the raw material cost of the alloy. On the other hand, due to Inconel 718′s wide application and large supply, its marginal cost has also been reduced.

Therefore, if you are hesitant between these two materials for your project, we recommend you to choose Inconel 718 first. It has better performance for the same price.

Overall, Inconel 718 is superior to Inconel X-750 in terms of corrosion resistance, high temperature strength and application fields due to the addition of more chromium and molybdenum elements. Therefore, Inconel 718 is a superior superalloy, both from a performance and cost perspective.

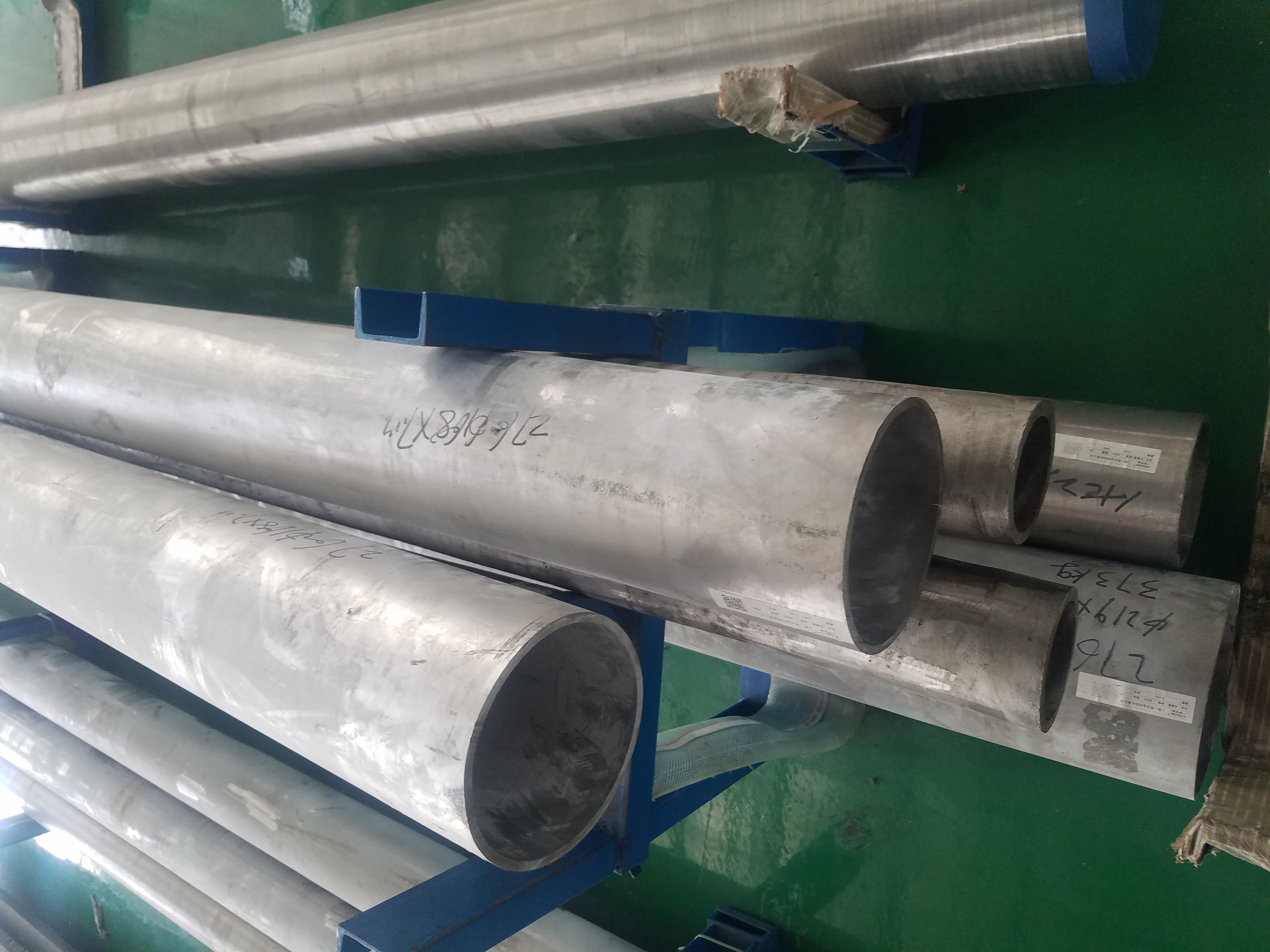

Tianjin Anton Metal Manufacture Co., Ltd. is a company specializing in the production of various nickel-based alloys, Hastelloy alloys and high-temperature alloy materials. The company was established in 1989 with a registered capital of 10.0 million, specializing in the production and sales of alloy materials. Anton Metal’s products are widely used in aerospace, chemical industry, electric power, automobile, nuclear energy and other fields, and can also provide customized alloy material solutions according to customer needs. If you need to know the price consultation of alloy materials or provide customized alloy material solutions, please feel free to contact the sales staff.

==========================================

www.antonmetal.com

ANTON METAL| Your specialty alloys manufacturer

Email: dominic@antonmetal.com

Phone: +8613132148618(wechat/whatsapp)

Post time: Dec-15-2023