-

AMS 5719 UNS S64152: A High-Strength, Corrosion-Resistant Steel Alloy

Steel alloys play a critical role in modern engineering, providing strength, durability, and corrosion resistance in various applications. Among the many steel alloys available, AMS 5719 UNS S64152 stands out as a high-strength and corrosion-resistant option. In this article, we will explore the ...Read more -

Know more about the Vacuum Casting

Vacuum casting is a manufacturing process that uses a silicone mold to create an exact replica of an object. It is a popular choice for manufacturing plastic parts in small batches due to its fast turnaround time and high precision. But what are the advantages and disadvantages of vacuum casting?...Read more -

Corrosion resistance of nickel and nickel alloys

Nickel and nickel alloys are widely used in the chemical industry due to their excellent thermodynamic stability and corrosion resistance. This article mainly introduces the corrosion resistance of several typical nickel-based alloys. Pure nickel shows good corrosion resistance in many corrosive ...Read more -

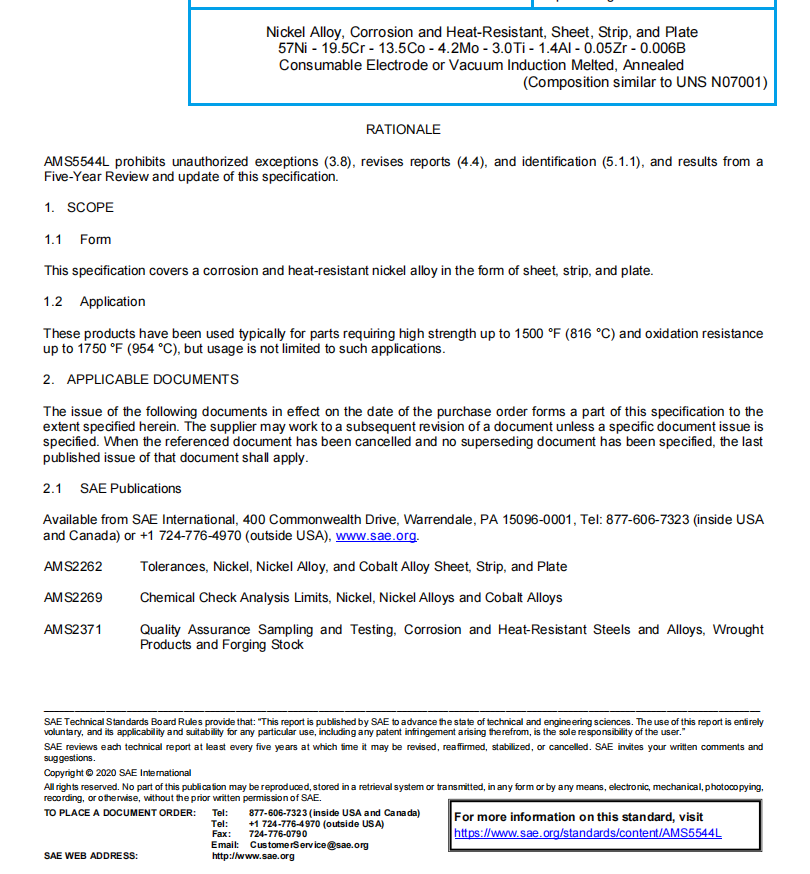

AMS5544L: Waspaloy SHEET & PLATE Manufacturer

AMS5544 is a high-strength, corrosion-resistant stainless steel alloy that is widely utilized in various industries for its exceptional mechanical properties and resistance to corrosion. This material is known for its high tensile strength, excellent toughness, and resistance to oxidation and cor...Read more -

Understanding AMS5707P Waspaloy bar and forging

AMS5707 is a high-strength, low-alloy steel that is widely used in various industries for its exceptional mechanical properties and resistance to corrosion. This material is known for its excellent strength-to-weight ratio, making it a popular choice for applications that require high performance...Read more -

What is AMS2241?

AMS2241 is a specification developed by the Society of Automotive Engineers (SAE) that outlines the requirements for the ultrasonic inspection of high-strength steel and alloy forgings. The specification provides guidelines for the ultrasonic testing of these forgings to ensure their structural i...Read more -

Inconel uses in the aerospace industry

What is Inconel? Inconel consists of a specific group of nickel alloys or nickel-chromium alloys. Inconel is durable, corrosion-resistant, rust-proof and very strong. These alloys are manufactured in different grades and come in different sizes and shapes. Why does the aerospace industry use Inco...Read more -

Application of Nickel Alloys in Chemical Processing

Nickel alloys are widely used in various industries, including chemical processing. These alloys offer excellent properties and are suitable for such applications. They are resistant to corrosion, high temperatures and wear. Its unique properties make it ideal for handling highly corrosive or abr...Read more -

The Difference Between Inconel 625 and Hastelloy C276

Inconel 625 and Hastelloy C276 are two highly corrosion-resistant nickel-based alloys that are widely used in various industries for their exceptional performance in aggressive environments. Both alloys offer excellent resistance to a wide range of corrosive media, high-temperature strength, and ...Read more -

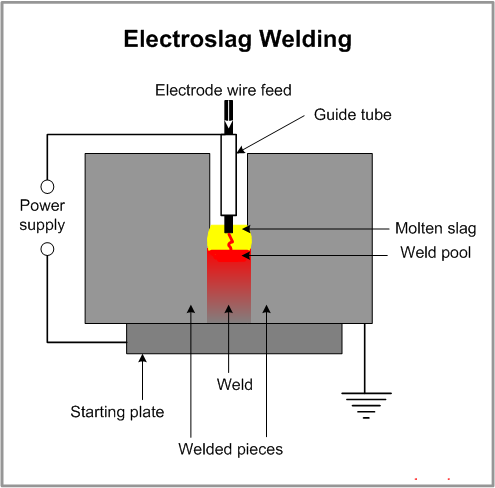

What is electroslag welding process?

Electroslag welding (ESW) is a highly efficient and versatile welding process that is widely used in various industries for joining thick sections of metal. It is particularly well-suited for welding large, thick components, such as pressure vessels, ship hulls, and heavy machinery. The process w...Read more -

Cold Welding vs. Spot Welding: Understanding the Differences and Applications

Welding is a fundamental process in metal fabrication and manufacturing, allowing for the joining of metal components to create complex structures and assemblies. Two common welding techniques, cold welding and spot welding, are widely used in various industries for their unique capabilities and ...Read more -

Common Metal Manufacturing Processes: A Comprehensive Overview

Metal manufacturing processes encompass a wide range of techniques and methods used to transform raw materials into finished metal products. These processes play a crucial role in various industries, including automotive, aerospace, construction, machinery, and consumer goods. From casting and fo...Read more