-

AMS4676: NICKEL-COPPER ALLOY BARS AND FORGINGS, CORROSION RESISTANT 66Ni – 3.0A1 – 0.6Ti – 30Cu

Introduction: In the realm of aerospace engineering, the development of advanced materials is crucial to meet the ever-increasing demands of performance, durability, and efficiency. One such groundbreaking alloy that has emerged is AMS4676. This article delves into the profound impact of AMS4676...Read more -

AMS2371: Quality Assurance Sampling and Testing Corrosion and Heat-Resistant Steels and Alloys Wrought Products and Forging Stock

Introduction: In the ever-evolving realm of statistics and data analysis, AMS2371 emerges as a game-changing tool for advanced statistical modeling and inference. This article aims to provide a comprehensive overview of AMS2371, highlighting its significance, key features, applications, and bene...Read more -

AMS2262: TOLERANCES Nickel and Nickel-Base Alloy Sheet and Strip

Introduction: In the dynamic world of technology and data analysis, AMS2262 emerges as a crucial tool for statistical modeling and experimental design. This article delves into the depths of AMS2262, exploring its significance, applications, key features, and benefits. So, buckle up and join us o...Read more -

What is Haynes 556 material?

Alloy materials are ubiquitous in our daily lives and they play an important role in various industrial fields. Today, we are going to introduce a special nickel-based alloy-HAYNES 556 alloy, also known as R30556 alloy. HAYNES 556 alloy is a high-temperature, high-strength, corrosion-resistant an...Read more -

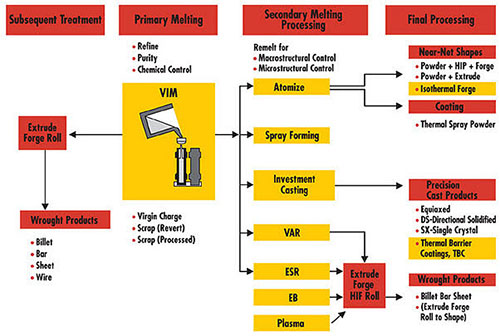

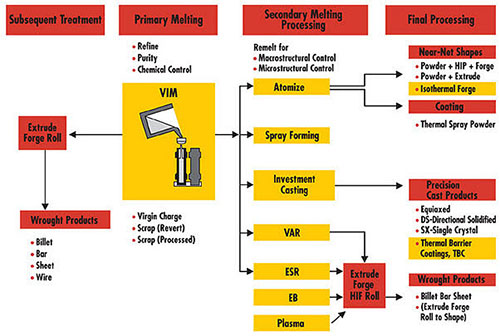

Vacuum induction melting method of high temperature alloys

The method of smelting high-temperature alloys in a vacuum induction furnace is to place the induction furnace in a vacuum and melt and refine the alloy through high temperatures. This method is called vacuum induction melting (VIM) of high-temperature alloys. At present, almost all highly alloye...Read more -

Incoloy 903 VS Incoloy 907 VS Incoloy 909

At the end of the 19th century, research found that when the nickel content in a nickel-iron alloy was about 36%, the linear expansion coefficient of the alloy was very low. Based on this property, a series of alloys with low linear expansion coefficients have been developed. Among them, Invar al...Read more -

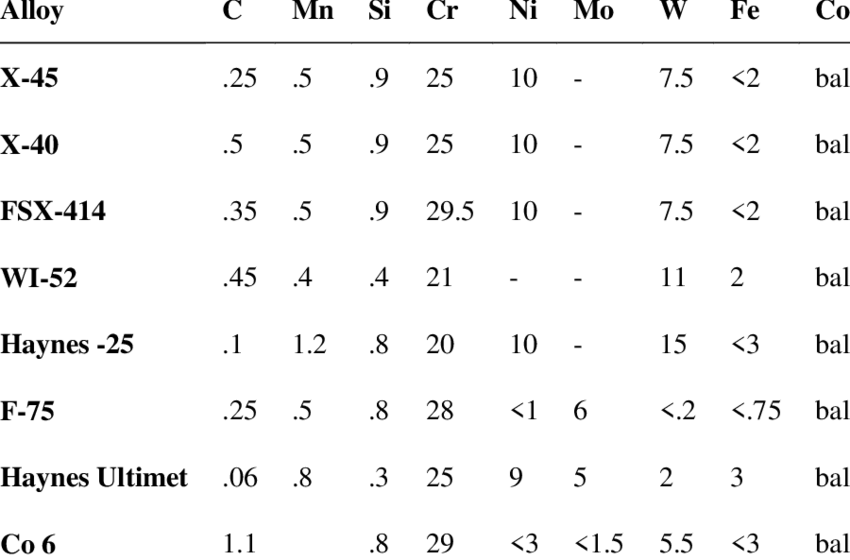

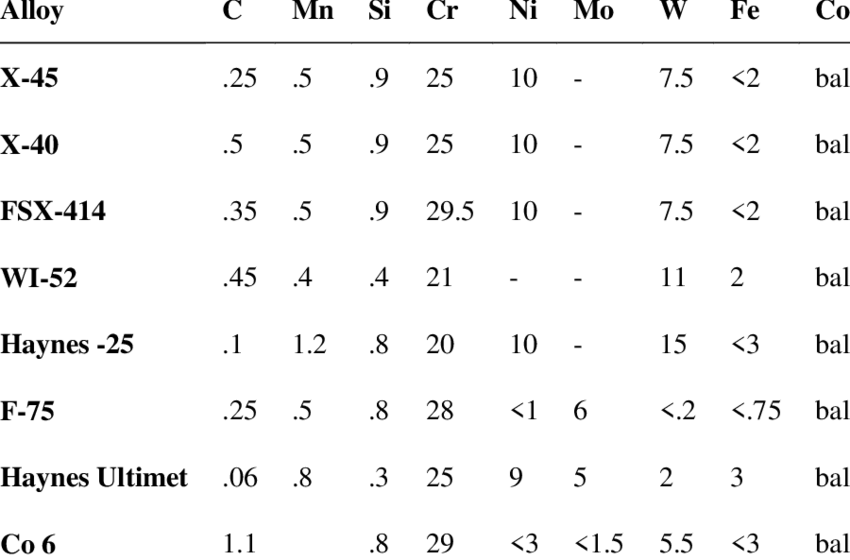

What are cobalt based superalloys?

Cobalt-based superalloys are materials used in high temperatures and extreme environments and have excellent high-temperature strength, corrosion resistance and wear resistance. Cobalt-based superalloys are mainly composed of elements such as cobalt, chromium, tungsten, nickel and aluminum. Cobal...Read more -

What is Monel alloy and used for?

Monel alloy is a nickel-copper alloy. The nickel element stabilizes the austenitic structure of the alloy, while the copper element brings excellent room temperature corrosion resistance to the alloy (especially in flowing seawater). For this reason, Monel alloys are often used in marine applicat...Read more -

Hastelloy X: Excellent Choice for High Temperature Environments

Hastelloy X nickel alloy is a nickel-chromium-molybdenum alloy with added cobalt and tungsten. Hastelloy X alloy exhibits excellent oxidation resistance at temperatures up to 1200°C and can also be used in neutral and reducing atmospheres. In addition, Hastelloy X alloy is resistant to carbonizat...Read more -

Effect of Co and Al Inconel 718 alloy on microstructure and mechanical properties

Inconel 718 alloy is a high-Nb age-strengthened Ni-Cr-Fe-based deformed high-temperature alloy with excellent high-temperature and mechanical properties and is widely used in aerospace and other fields. However, when the service temperature of Inconel 718 alloy exceeds 650°C, the γ” phase w...Read more -

Comparison of Inconel 625 and Incoloy 825

In industrial projects, the materials chosen are as important as the design. Two common alloys are Inconel 625 and Incoloy 825 alloy. Let’s compare these two materials so you can make an informed decision for your project. Alloy Inconel 625 and Alloy Incoloy 825 are nickel-based superalloys devel...Read more -

Inconel 725 VS Inconel 625: What’s the Difference?

Inconel 725 and Inconel 625 If you’re an engineer or metal fabricator, you know that when it comes to metals, performance matters. Inconel is a super alloy commonly used for its superior strength and corrosion resistance. But which type should you choose – Inconel 725 or Inconel 625? ...Read more