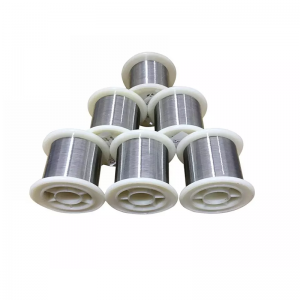

Rene 41 nickel wire rod, Rene 41 round bar, Rene 41 plate, Rene 41 sheet, Rene 41 strip

▪ UNS N07041

▪ Werkstoff Nr. 2.4973

▪ AISI 683

▪ SAE AMS 5712 Bar

▪ SAE AMS 5545 Sheet, Strip and Plate

▪ GE B50T59 Sheet, Plate, Strip, Bars and Forgings

▪ GE B50TF76C Sheet, Plate, Strip

▪ GE B50TF109C Sheet, Strip, Plate, Solution Treated

▪ SAE AMS 5713 Bar (VAC MELT)

▪ SAE AMS 5800 Welding Wire

▪ MSRR 9500/241 Welding Wire

▪ Aircraft engine components

▪ Aircraft turbine blades

▪ Aircraft wheel

▪ Aircraft combustion chamber liners

▪ Aircraft structural hardware

▪ Afterburner parts

| C | Si | Ni | Co | Al | Fe | Mn | Cr | Mo | Ti | B |

| 0.06 - 0.12 | 0.20 max | Bal | 10-12 | 1.4-1.6 | 5.0 max | 0.1 max | 18-20 | 9.0-10.5 | 3-3.3 | 0.003-0.01 |

| Material | Tensile Strength ksi | Yield Strength ksi | Elongation in 4D | Reduction of Area | Hardness |

| Rene 41 (R41) Solution Treated Bar |

363 HB max | ||||

| Rene 41 (R41) Solution Treated Aged Bar |

170 | 130 | 8 | 10 | 311 HB min |

| Rene 41 (R41) Solution Treated Sheet |

170 max | 100 max | 30 max | 30HRC max | |

| Rene 41 (R41) Solution Treated Aged Sheet |

170 min | 130 min | 10 min | 35 HRC min |