ASTM B575 Hastelloy C-4 nickel strip,UNS N06455nickel plate price, Hastelloy C-4 nickel bar

▪ ASTM B574

▪ ASTM B575

▪ ASTM B619

▪ ASTM B622

▪ ASTM B626

▪ DIN 2.4610

The chemical composition of Hastelloy C-4 is outlined in the following table.

| Element | Content (%) |

| Chromium, Cr | 14-18 |

| Molybdenum, Mo | 14-17 |

| Iron, Fe | 3 max |

| Cobalt, Co | 2 max |

| Manganese, Mn | 1 max |

| Titanium, Ti | 0.7 max |

| Silicon, Si | 0.08 max |

| Phosphorus, P | 0.04 max |

The mechanical properties of Hastelloy C-4 are outlined in the following table.

| Properties | Metric | Imperial |

| Tensile strength | 738 MPa | 107000 psi |

| Yield strength ( @ 0.2% offset) | 492 MPa | 71400 psi |

| Elastic modulus | 211 GPa | 30600 ksi |

| Elongation at break (in 50.8 mm) | 42% | 42% |

Hastelloy C-4 can be machined using conventional methods.

Hastelloy C-4 can be easily formed using conventional techniques.

Except submerged arc and oxy-acetylene welding methods, Hastelloy (r ) C-4 can be welded using all other welding methods.

Hastelloy C-4 is heat treated by annealing at 1066°C (1950°F) followed by quenching.

Hastelloy C-4 is hot forged at 955 to 1177°C (1750 to 2150°F).

Hastelloy C-4 is hot extruded or hot worked similar to that of stainless steels.

Hastelloy C-4 can be cold worked using conventional methods.

Hastelloy C-4 is annealed at 1066°C (1950°F) followed by quenching.

Hastelloy C-4 is aged at 649°C (1200°F) for 10 h in order to improve its yield strength and ductility without decreasing its ultimate tensile strength.

Hastelloy C-4 is hardened by cold working.

▪ Chemical processing equipment

▪ Nuclear fuel processing

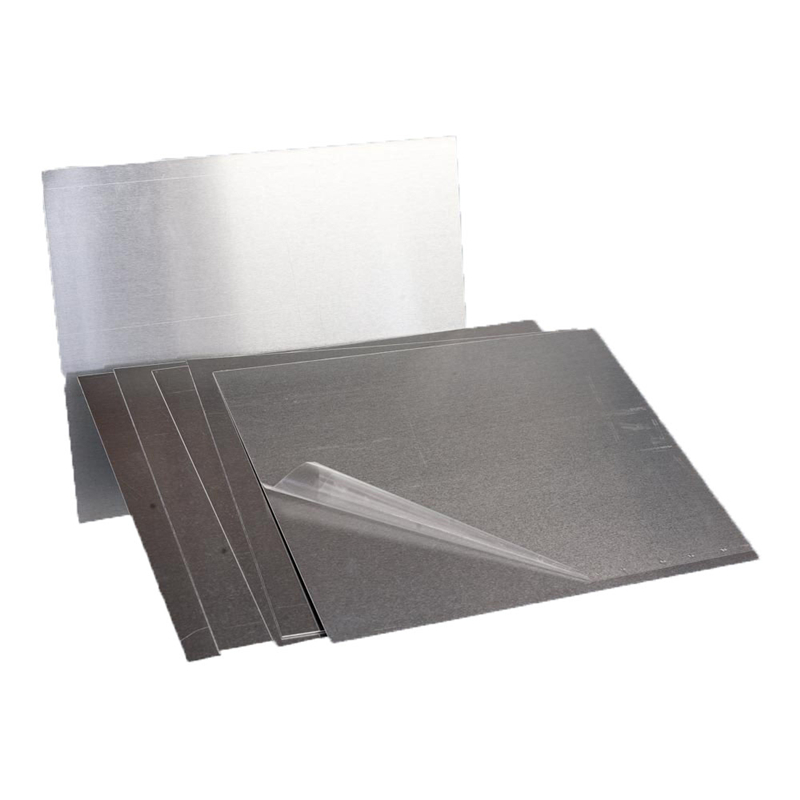

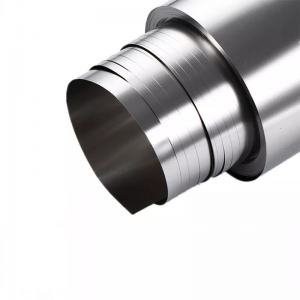

| Hastelloy C-4 available sizes and specifications | |

| Grade | Hastelloy C-4 |

| Nickel plate | Thickness: 0.3mm - 150.0mm Width: 1000mm - 3000mm |

| Nickel strip/ nickel foil | Thickness: 0.02mm - 16.0mm Width: 5mm - 3000mm |

| Nickel coil | Thickness: 0.3mm - 16.0mm Width: 1000mm - 3000mm |

| Nickel pipe | Outside diameter: 6mm - 1219mm Thickness: 0.5mm - 100mm |

| Nickel Capillary Pipe | Outside diameter: 0.5mm - 6.0mm Thickness: 0.05mm - 2.0mm |

| Nickel bar | Diameter: Ф4mm - Ф600mm |

| Nickel wire rod | Diameter:Ф0.01mm - Ф6mm |