The process of producing Hastelloy seamless pipes can be divided into the following steps: raw material preparation, steel pipe production, heat treatment, cold working, inspection and testing, and packaging for delivery. There are some considerations that require special attention in each step.

First of all, raw material preparation is the first step in producing Hastelloy seamless pipes. Raw materials include steel billets and other alloy materials. The selection of steel billets should be based on the requirements of different grades of Hastelloy seamless pipes, which requires reference to relevant standards and specifications. When selecting alloy materials, you need to ensure that their composition and properties meet production requirements.

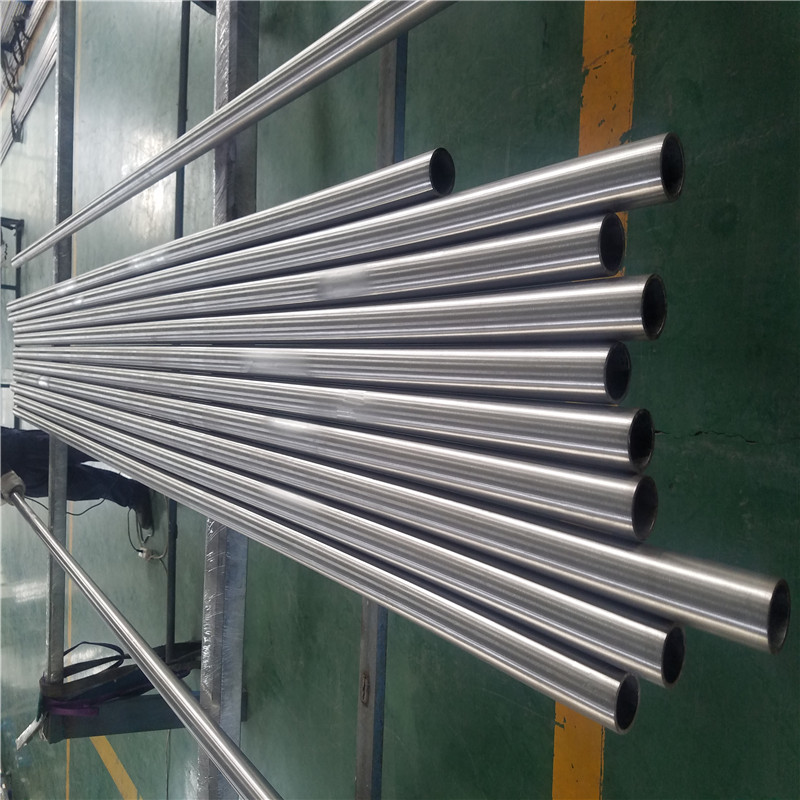

The second step is steel pipe production. This process usually includes hot rolling or cold rolling, piercing, pickling, extrusion, heating and sizing, cooling, continued rolling, grinding and other processes. Hot rolling or cold rolling is to pass the steel billet through a series of rolling processes to gradually reduce its thickness to produce a round-shaped pipe. Perforation is to heat the rolled steel billet to high temperature, and use a steel cone or steel pipe cold bending machine to pierce the center position. Pickling is to remove surface oxide scale and dimensional errors caused by rolling and perforation. The extrusion process uses an extruder to extrude the pickled steel billet through modules to obtain a more accurate outer diameter and inner diameter. Heating sizing is to further control the accuracy of the outer diameter and restore the residual stress after cold working. Cooling and continued rolling processes provide further control over tube dimensions and properties.

During the entire steel pipe production process, the following points need to be noted: First, suitable rolling processes and equipment must be used for steel pipes of different specifications. Secondly, the temperature, rolling force, roll size and other parameters of each process need to be strictly controlled to ensure the quality of the finished steel pipe. In addition, waste products generated during production also need to be sorted and processed.

The third step is heat treatment. This step is to improve the structure and performance of the steel pipe so that it can meet the design requirements. Common heat treatment methods include annealing, normalizing, quenching and tempering. During the heat treatment process, attention should be paid to controlling the heating temperature, holding time and cooling rate to ensure that the steel pipe obtains the required structure and performance.

The fourth step is cold processing. Cold working is to further improve the dimensional accuracy and surface quality of steel pipes. Common cold working methods include cold drawing, cold rolling, cold drawing and cold extrusion. During the cold working process, it is necessary to control the cold working temperature, cold working rate and cold working times, as well as the selection and use of processing lubricants to ensure the quality of the steel pipe.

The fifth step is inspection and testing. This step is to check whether the quality and performance of the steel pipe meet the standard requirements. Common inspection and testing methods include chemical composition analysis, mechanical property testing, non-destructive testing and dimensional measurement. When conducting chemical composition analysis, it is necessary to use accurate and reliable analytical instruments and perform necessary calibration and verification. In mechanical property testing, it should be carried out according to standard testing methods, and mechanical properties should be calculated and evaluated. Non-destructive testing is to find defects and cracks inside steel pipes. Commonly used methods include ultrasonic testing, radiographic testing and magnetic particle testing. Dimensional measurement is to check the dimensional accuracy and appearance quality of steel pipes. Commonly used methods include diameter measurement, wall thickness measurement and length measurement.

The last step is to package and leave the factory. During the packaging and delivery process, you need to pay attention to the following points: First, choose packaging materials suitable for the size and weight of the steel pipe, such as wooden boxes, iron frames, plastic films, etc. Secondly, the packaging materials must have sufficient strength and protective properties to avoid damage to the steel pipes during transportation and storage. In addition, attention should be paid to anti-rust treatment of steel pipes to prevent them from being oxidized and corroded during storage and transportation.

In short, the process of producing Hastelloy seamless pipes includes raw material preparation, steel pipe production, heat treatment, cold processing, inspection and testing, and packaging for delivery. In each step, attention needs to be paid to controlling process parameters, selecting suitable equipment and tools, and conducting necessary inspections and tests to ensure the production of high-quality Hastelloy seamless pipes that meet standard requirements.

Tianjin Anton Metal Manufacture Co., Ltd. is a company specializing in the production of various nickel-based alloys, Hastelloy alloys and high-temperature alloy materials. The company was established in 1989 with a registered capital of 10.0 million, specializing in the production and sales of alloy materials. Anton Metal’s products are widely used in aerospace, chemical industry, electric power, automobile, nuclear energy and other fields, and can also provide customized alloy material solutions according to customer needs. If you need to know the price consultation of alloy materials or provide customized alloy material solutions, please feel free to contact the sales staff.

==========================================

www.antonmetal.com

ANTON METAL| Your specialty alloys manufacturer

Email: dominic@antonmetal.com

Phone: +8613132148618(wechat/whatsapp)

Post time: Dec-13-2023