Stainless steel is a go-to material when it comes to industrial applications that require strength, resistance to corrosion, and durability. However, some environments are so harsh that even the finest stainless steels may fail, leading to catastrophic consequences. In such cases, 254SMo stainless steel stands out as an exceptional material that can withstand extreme conditions.

This article will cover everything you need to know about 254SMo stainless steel, including its properties, applications, standard specifications, ASTM equivalent, and differences from other similar materials like AL-6XN. We’ll also delve into ANTON METAL’s more than two decades of experience in providing high-quality 254SMo products to industries worldwide.

What is 254SMo Stainless Steel?

254SMo (UNS S31254) is a super austenitic stainless steel with excellent resistance to pitting and crevice corrosion in seawater and other aggressive environments containing chlorides. It contains high levels of molybdenum, nickel, and chromium, which enhance its corrosion resistance and make it suitable for use in harsh and corrosive environments.

Chemical Composition of 254SMo Stainless Steel

The chemical composition of 254SMo stainless steel is as follows:

- Chromium (Cr): 19.5 – 20.5%

- Nickel (Ni): 17.5 – 18.5%

- Molybdenum (Mo): 6 – 6.5%

- Copper (Cu): 0.5 – 1.0%

- Nitrogen (N): 0.18 – 0.22%

- Carbon (C): 0.02% max

- Silicon (Si): 0.8% max

- Manganese (Mn): 1% max

- Phosphorus (P): 0.03% max

- Sulfur (S): 0.01% max

Mechanical Properties of 254SMo Stainless Steel

The mechanical properties of 254SMo stainless steel are as follows:

- Tensile strength: 650 – 850 MPa

- Yield strength: 300 – 350 MPa

- Elongation: 35% min

- Hardness: 90 HRB max

Applications of 254SMo Stainless Steel

Due to its excellent corrosion resistance and high strength, 254SMo stainless steel is widely used in a variety of applications, including:

- Chemical processing equipment

- Desalination plants

- Pulp and paper production

- Oil and gas exploration and production

- Marine engineering

- Heat exchangers

- Food processing equipment

- Pharmaceutical production

- Pollution control equipment

- Nuclear power plants

Standard Specifications and ASTM Equivalent of 254SMo Stainless Steel

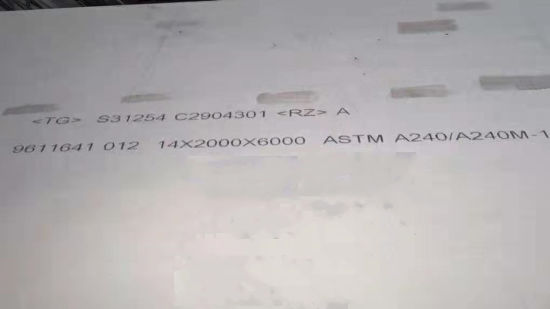

The standard specifications for 254SMo stainless steel are as follows:

- UNS: S31254

- EN: 1.4547

- ASTM: A240, A276, A312, A479, B677, B688, B691, F44

254SMo stainless steel is often compared to AL-6XN due to their similar chemical composition and excellent corrosion resistance. However, 254SMo has higher levels of molybdenum and nitrogen, which enhance its corrosion resistance and make it more suitable for use in highly corrosive environments.

ANTON METAL’s Experience with 254SMo Stainless Steel

ANTON METAL is a leading supplier of high-quality 254SMo products, including pipes, round bars, and plates. With over two decades of experience in providing exceptional quality materials to industries worldwide, ANTON METAL has established itself as a trusted partner for those seeking reliable and durable materials for their projects.

At ANTON METAL, we are committed to delivering top-quality products that meet our clients’ precise specifications. Our 254SMo stainless steel products are manufactured using the latest technology and strict quality control procedures to ensure that they meet the highest standards of quality and performance.

Post time: Jun-25-2023