Duplex stainless steels are a family of stainless steels that exhibit a two-phase microstructure consisting of both austenite and ferrite. The combination of these two phases results in a material with excellent mechanical properties, high strength, and good corrosion resistance. S32550 is a duplex stainless steel that belongs to this family of steels.

In this article, we will take an in-depth look at S32550, its chemical composition, mechanical properties, applications, standards, ASTM equivalent, and the difference between S32760. We will also explore ANTON METAL’s more than 20 years of experience in supplying high-quality duplex stainless steels to various industries worldwide.

Chemical Composition of S32550

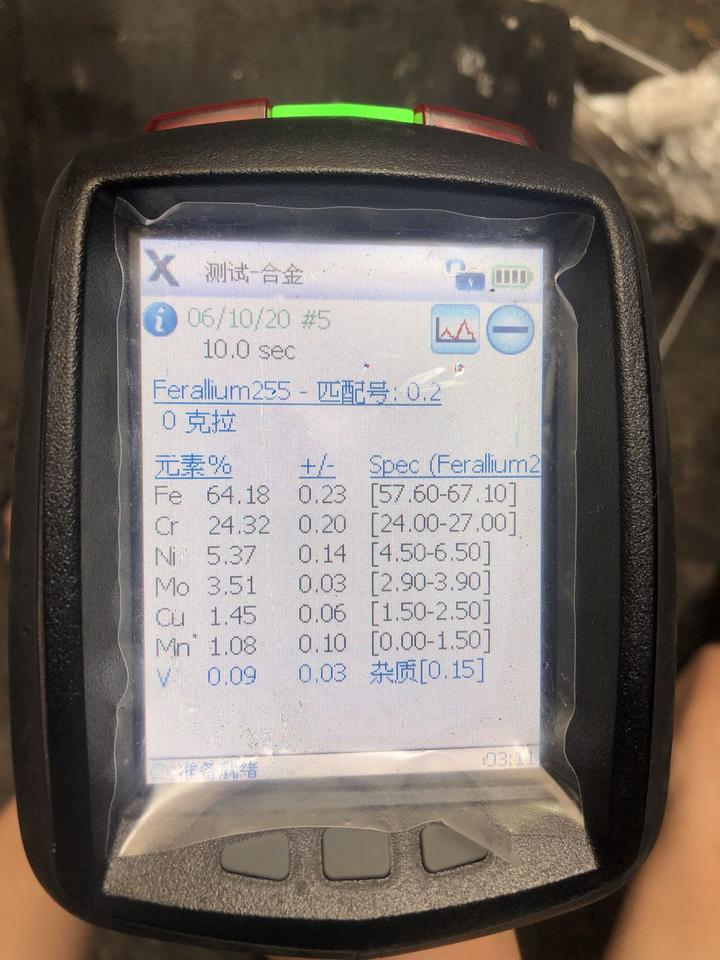

S32550 is a super duplex stainless steel with a chemical composition that includes chromium (Cr), nickel (Ni), molybdenum (Mo), nitrogen (N), and manganese (Mn). The table below shows the chemical composition of S32550.

| Element | Minimum | Maximum |

|---|---|---|

| C | - | 0.03 |

| Cr | 24.0 | 27.0 |

| Ni | 4.5 | 6.5 |

| Mo | 2.9 | 3.9 |

| N | 0.20 | 0.30 |

| Mn | - | 2.0 |

| Si | - | 1.0 |

| P | - | 0.035 |

| S | - | 0.015 |

Mechanical Properties of S32550

S32550 has excellent mechanical properties due to its duplex microstructure. It has a high yield strength and tensile strength, as well as good ductility and toughness.

The table below shows the typical mechanical properties of S32550 in the annealed condition.

| Property | Value |

|---|---|

| 0.2% Yield Strength | 550 MPa |

| Ultimate Tensile Strength | 800 – 1000 MPa |

| Elongation | 25% |

| Hardness, Rockwell C | 28 – 32 HRC |

| Charpy Impact | 100 J at -40°C (-40°F) |

Applications of S32550

S32550 is widely used in various applications due to its excellent corrosion resistance, high strength, and good weldability. It is commonly used in the following industries:

- Oil and Gas: S32550 is an excellent material for oil and gas production equipment such as subsea pipelines, umbilicals, and risers. It offers high resistance to stress corrosion cracking (SCC), pitting, and crevice corrosion in harsh environments.

- Chemical Processing: S32550 is ideal for chemical processing equipment such as reactors, heat exchangers, and tanks. Its high corrosion resistance makes it suitable for handling corrosive chemicals such as sulfuric acid and hydrochloric acid.

- Marine: S32550 is commonly used in marine applications due to its excellent resistance to seawater corrosion. It is used in offshore platforms, seawater desalination plants, and shipbuilding.

Standards and ASTM Equivalent

S32550 is a super duplex stainless steel that conforms to various international standards, including ASTM A240, EN 1.4507, and UNS S32550. The ASTM equivalent of S32550 is ASTM F61.

The Difference Between S32550 and S32760

S32550 and S32760 are both super duplex stainless steels that belong to the same family of duplex stainless steels. They have similar chemical compositions, but S32760 has higher chromium, molybdenum, and nitrogen contents than S32550. This makes S32760 more resistant to corrosion in aggressive environments such as seawater.

ANTON METAL: More Than 20 Years of Experience in Supplying Duplex Stainless Steels

ANTON METAL is a leading supplier of high-quality duplex stainless steels, including S32550, to various industries worldwide. With more than 20 years of experience, ANTON METAL has built a reputation for providing reliable, efficient, and cost-effective solutions to its customers.

The company’s commitment to quality is reflected in its certifications, which include ISO 9001:2015, PED 2014/68/EU, and AD2000 W0. ANTON METAL also offers customized solutions to meet its customers’ specific requirements.

Conclusion

In conclusion, S32550 is a high-performance duplex stainless steel with excellent corrosion resistance, mechanical properties, and a wide range of applications in various industries. Its duplex microstructure provides high strength, good ductility, and toughness, making it suitable for use in harsh environments.

S32550 conforms to various international standards, including ASTM A240, EN 1.4507, and UNS S32550. The ASTM equivalent of S32550 is ASTM F61. It is important to note that while S32550 and S32760 share similar chemical compositions, S32760 has higher chromium, molybdenum, and nitrogen contents than S32550, making it more resistant to corrosion in aggressive environments such as seawater.

ANTON METAL’s more than 20 years of experience in supplying high-quality duplex stainless steels to various industries worldwide makes it a reliable partner for customers looking for customized solutions. With certifications such as ISO 9001:2015, PED 2014/68/EU, and AD2000 W0, ANTON METAL ensures the quality and reliability of its products.

In summary, S32550 is a highly versatile and durable material that is well-suited for demanding applications in harsh environments. Its excellent resistance to corrosion, high strength, and good weldability make it an ideal choice for industries such as oil and gas, chemical processing, and marine. ANTON METAL’s experience, expertise, and commitment to quality make it a reliable partner for customers seeking high-quality duplex stainless steels.

Post time: Jun-25-2023