Structure and application of space furnace nozzle

The space furnace gasification burner is one of the key equipment in the aerospace field. Its main function is to fully mix dry coal powder and oxygen to achieve an efficient combustion reaction, thereby producing high-temperature and high-pressure gas to provide power for space launches. According to different functions, space furnace nozzles can be divided into three types: ignition burners, starting burners and process burners. Among them, the ignition burner is mainly used to ignite the start-up burner, which has the characteristics of low energy and short working time; the start-up burner is used to raise the temperature and pressure of the furnace environment to the specified working condition and ignite the process burner. It has the characteristics of large load adjustment range and strict temperature range control; while the process burner is used to complete the reaction and has the characteristics of high stability and long-term effectiveness.

The space furnace nozzle adopts a split burner structure, which is composed of an ignition burner, a starting burner and a process burner. Each burner has its own function and cooperates with each other to complete the entire combustion reaction process. The dry pulverized coal feed is transported by three pulverized coal pipes, and high-pressure CO2/N2 is used as a carrier to ensure that the pulverized coal enters the pulverized coal mixing chamber and is evenly distributed, then ejected from the nozzle, and is fully mixed with the spiral oxygen in the furnace to complete the process. reaction. The pulverized coal pipe runs through the outer water-cooling jacket, and the cooling water temperature is used to heat the pulverized coal to ensure efficient combustion reactions.

Tianjin Anton Metal Products Co., Ltd. was established in 1989 with a registered capital of 10 million. It specializes in the production of various nickel-based alloys, Hastelloy alloys and high-temperature alloy materials. It is one of the leading manufacturers of special alloy materials in China. In aerospace furnace nozzles, nickel-based alloys, high-temperature alloys and Hastelloy materials produced by Anton Metal Company are widely used.

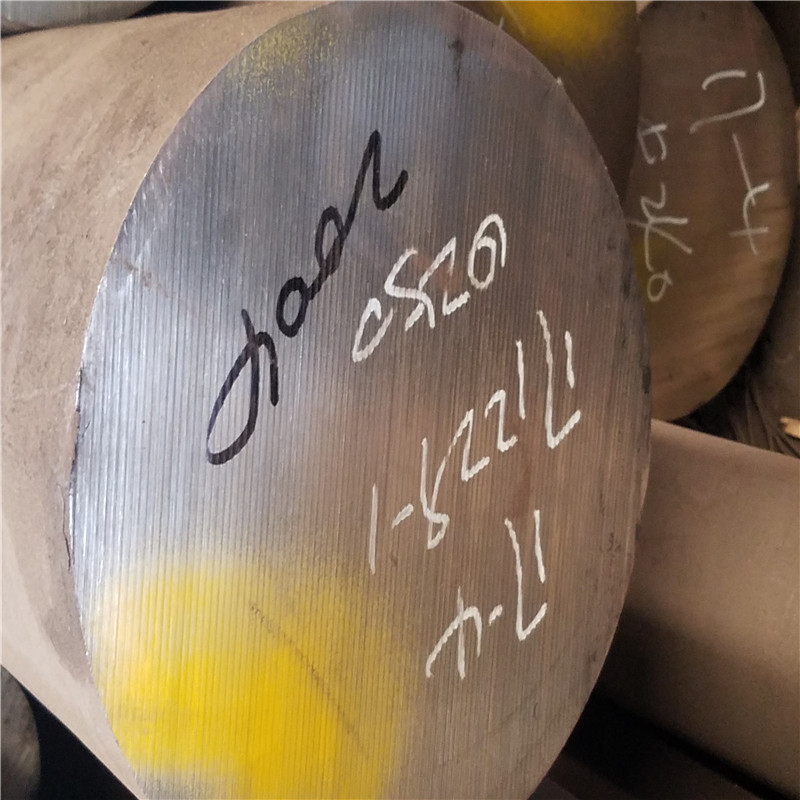

The nickel-based alloy materials produced by Anton Nickel Alloy Company include Hastelloy C-276, Hastelloy C-22, Inconel 625, etc. These alloy materials have excellent corrosion resistance and high-temperature strength and are widely used in chemical, petrochemical, aerospace and other fields. in high-temperature corrosive environments. In space furnace nozzles, these alloy materials can be used in the cooling coil and water jacket of the burner to provide better corrosion resistance and wear resistance.

In addition, Anton Metal Company also produces alloy materials and cobalt-based alloys, such as Inconel 718, Inconel 600, MP159, Haynes 263, Haynes 188, MP35N, etc. These alloy materials have high high-temperature strength and excellent oxidation resistance and are widely used in Used in aviation, aerospace, nuclear industry and other fields. In the space furnace nozzle, these high-temperature alloy materials can be used in key parts such as the structural components of the burner and the nozzle to provide better high-temperature strength and corrosion resistance and ensure the long-term stable operation of the space furnace nozzle.

In addition, Anton Metal Company also produces Hastelloy materials, such as Hastelloy X, Hastelloy B-2, etc. These alloy materials have excellent high-temperature strength, corrosion resistance and wear resistance, and are widely used in aerospace, petrochemicals, and nuclear power and other fields. In the space furnace nozzle, these Hastelloy materials can be used in key parts such as the burner nozzle and structural components to provide better wear and corrosion resistance and ensure the stable operation and long-term service life of the space furnace nozzle.

In short, the space furnace nozzle is one of the key equipment for space launch, and its structure and material selection have a crucial impact on its performance and stability. The nickel-based alloys, high-temperature alloys and Hastelloy materials produced by Anton Metal Company have excellent corrosion resistance, high-temperature strength and wear resistance. They are widely used in various key parts of the space furnace nozzle, providing stability for space launches. Reliable power guarantee.

Tianjin Anton Metal Manufacture Co., Ltd. is a company specializing in the production of various nickel-based alloys, Hastelloy alloys and high-temperature alloy materials. The company was established in 1989 with a registered capital of 10.0 million, specializing in the production and sales of alloy materials. Anton Metal’s products are widely used in aerospace, chemical industry, electric power, automobile, nuclear energy and other fields, and can also provide customized alloy material solutions according to customer needs. If you need to know the price consultation of alloy materials or provide customized alloy material solutions, please feel free to contact the sales staff.

==========================================

www.antonmetal.com

ANTON METAL| Your specialty alloys manufacturer

Email: dominic@antonmetal.com

Phone: +8613132148618(wechat/whatsapp)

Post time: Dec-13-2023