Hastelloy alloy C-22 supplier,nickel alloy hastelloy C22,alloy C22 plate,alloy C-22 pipe Description:

CORROSION RESISTANCE

Alloy C22 is one of the most corrosion-resistant alloys available, even outperforming C276 and 625. It is resistant to almost all reducing and oxidizing environments, including strong oxidizers, seawater, and organic acids. In addition, C22 has excellent resistance to chloride-induced localized corrosion, including pitting, crevice corrosion, and stress corrosion cracking.

OXIDATION RESISTANCE

C22 has excellent resistance to oxidation, carburization, and sulfidation at elevated temperatures. However, C22 should not be used at temperatures above 1250°F due to the possible formation of embrittling phases.

MECHANICAL PROPERTIES

C22 is typically provided in the annealed condition with a minimum yield strength of 45 ksi. However, C22 can be cold worked to higher strength levels.

HEAT TREATMENT

C22 is typically annealed at 2050°F (1121°C), followed by rapid cooling.

WORKABILITY

C22 can be hot worked or cold worked. However, C22 work-hardens rapidly. Therefore, cold working must often be performed in stages with intervening anneals. Parts should be annealed after cold working.

The exceptional corrosion resistance of C22 has promoted its use in many different markets wherever harsh environments are encountered, including the chemical process, pharmaceutical, food processing, oil & gas, power generation, and the paper industries. CRA offers specialty alloy C22 seamless pipe & tube for use in multiple industries and applications, including:

▪ Chemical processes

▪ Food Processing

▪ Pharmaceutical Industry

▪ Oil & Gas

▪ Power Generation

▪ Pulp & Paper Industries

| Composition | Ni | Cr | Fe | Mo | W | Co | C | Mn | Si | S | V | P | Ti | |

| Content (%) | Min. | Bal. | 20 | 2 | 2.5 | |||||||||

| Max. | 22.5 | 6 | 3.5 | 2.5 | 0.015 | 0.5 | 0.08 | 0.02 | 0.35 | 0.02 | ||||

| Tensile Strength (σb/MPa) | Yield Strength (σp0.2/MPa) | Elongation (σ5/%) |

| 758 | 363 | 62 |

| Bar | Sheet/Strip | Pipe |

| ASTM B462 ASTM B574 |

ASTM B575

ASTM B906 |

ASTM B622 ASTM B619 ASTM B626 |

| Hastelloy C-22 available sizes and specifications | |

| Grade | Hastelloy C-22 |

| Nickel plate | Thickness: 0.3mm - 150.0mm Width: 1000mm - 3000mm |

| Nickel strip/ nickel foil | Thickness: 0.02mm - 16.0mmWidth: 5mm - 3000mm |

| Nickel coil | Thickness: 0.3mm - 16.0mm Width: 1000mm - 3000mm |

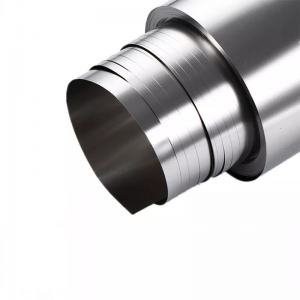

| Nickel pipe | Outside diameter: 6mm - 1219mm Thickness: 0.5mm - 100mm |

| Nickel Capillary Pipe | Outside diameter: 0.5mm - 6.0mm Thickness: 0.05mm - 2.0mm |

| Nickel bar | Diameter: Ф4mm - Ф600mm |

| Nickel wire rod | Diameter:Ф0.01mm - Ф6mm |