Hastelloy is the brand name for a group of corrosion-resistant alloys. C-22 and C-276 are both Hastelloys, which can cause confusion, but Hastelloy C-22 has better overall corrosion resistance than Hastelloy C-276 and is often referred to as an upgraded version of Hastelloy C-276.

What is Hastelloy C22?

Hastelloy C22, also known as Alloy C22, is a versatile austenitic nickel-chromium-molybdenum-tungsten alloy with excellent resistance to pitting, crevice corrosion and stress corrosion cracking. The high chromium content provides good resistance to oxidizing media, while the molybdenum and tungsten content provides good resistance to reducing media. This nickel steel alloy is also resistant to oxidizing aqueous media such as mixtures of wet chlorine and nitric acid or oxidizing acids containing chloride ions. Other corrosive agents that Hastelloy C-22 is resistant to include oxidizing acid chlorides, wet chlorine, formic and acetic acids, ferric and copper chlorides, sea water, brine, and many mixed or contaminated organic and inorganic chemical solutions.

What is Hastelloy C276?

Hastelloy C276 is a nickel-chromium-molybdenum wrought alloy widely considered the most versatile corrosion-resistant alloy. The alloy resists the formation of grain boundary precipitates in the weld heat affected zone, making it suitable for most welding chemical process applications. Alloy C-276 is also resistant to pitting corrosion, stress corrosion cracking and oxidizing atmospheres up to 1900°F. Alloy C-276 offers excellent resistance to a wide range of chemical environments.

Hastelloy C22 vs. Hastelloy C276:

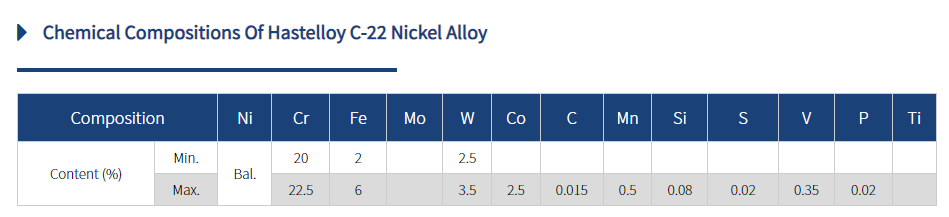

Hastelloy C22 chemical composition:

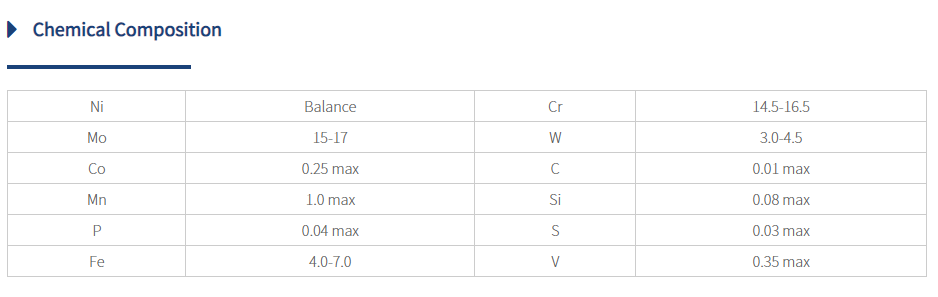

Hastelloy C276 chemical composition:

Hastelloy C22 and C276 Characteristics:

Hastelloy C22 and Hastelloy C276 are two variations of the same nickel-molybdenum alloy. Both are highly corrosion-resistant in a wide range of applications, but the sturdiness of the two differs greatly. Hastelloy C276 is more resistant to localized attack than Hastelloy C22, allowing it to operate in chlorine-based environments at high temperatures and pressures. Additionally, due to its increased iron content, Hastelloy C276 offers superior resistance to chloride pitting and crevice corrosion compared to similar products. Considering these properties, it is clear that for applications in harsh conditions, especially those related to chemical processing, Hastelloy C276 offers enhanced durability and strength, making it an ideal choice for most needs.

Hastelloy c22 and Hastelloy c276 machinability:

Hastelloy C22 and Hastelloy C276 are two of the easiest alloys on the market today to machine. Both have excellent machining properties, but there are some differences between them. Hastelloy C22 has better corrosion resistance than Hastelloy C276, is easy to cut and drill, and has strong weldability. In comparison, Hastelloy C276 has a higher chromium content, which improves strength, but is also more complex to machine. Nonetheless, the properties of both alloys make them suitable for many machining applications, and in some cases the two can be used interchangeably.

Hastelloy c22 and Hastelloy c276 prices:

Cost is always a factor when choosing the right alloy for a project. Hastelloy C22 and Hastelloy C276 are two popular alloys in the Hastelloy family, both with their own unique advantages. While the two alloys may be similar in composition, there may be significant differences in pricing. Depending on the requirements of an individual project, one alloy may be better than another due to price or other considerations. Ultimately, it’s worth carefully studying the technical details and pricing of each option before deciding which alloy is best for your application.

Tianjin Anton Metal Manufacture Co., Ltd. is a company specializing in the production of various nickel-based alloys, Hastelloy alloys and high-temperature alloy materials. The company was established in 1989 with a registered capital of 10.0 million, specializing in the production and sales of alloy materials. Anton Metal’s products are widely used in aerospace, chemical industry, electric power, automobile, nuclear energy and other fields, and can also provide customized alloy material solutions according to customer needs. If you need to know the price consultation of alloy materials or provide customized alloy material solutions, please feel free to contact the sales staff.

==========================================

www.antonmetal.com

ANTON METAL| Your specialty alloys manufacturer

Email: dominic@antonmetal.com

Phone: +8613132148618(wechat/whatsapp)

Post time: Jan-09-2024