Alloy 46 is a beneficial material favored in industries that require high strength, durability, heat resistance, and corrosion resistance. But what is alloy 46? What is unique about this alloy and why is it so sought after? In this article, we’ll take an in-depth look at Alloy 46, including its composition, mechanical and physical properties, uses, corrosion resistance, heat treatment, machining, and welding techniques.

What is Alloy 46?

Alloy 46 is an advanced nickel-chromium alloy containing cobalt, molybdenum and tungsten. It has excellent mechanical strength, heat resistance and corrosion resistance at high temperatures, making it ideal for aerospace and chemical processing applications. The combination of these properties makes Alloy 46 an excellent choice where cost-effectiveness and reliability are key factors.

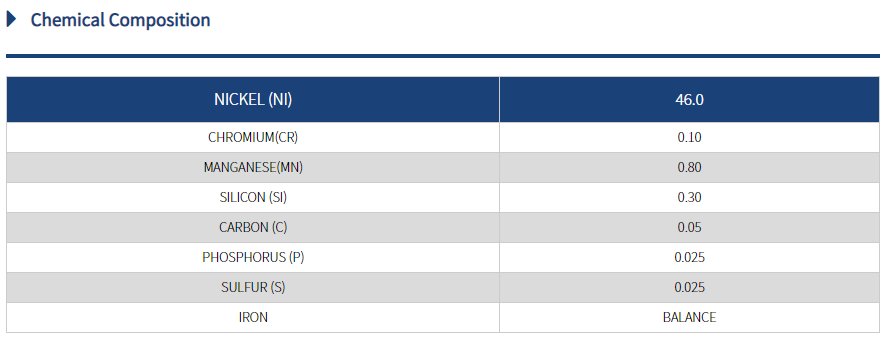

Alloy 46 Chemical Composition:

Alloy 46 is a nickel-iron alloy with a composition of approximately 46% nickel and 54% iron. Other elements found in smaller amounts include carbon, manganese, silicon, sulfur and phosphorus. Its high nickel content gives it excellent corrosion resistance, making it a popular material for manufacturing a variety of components.

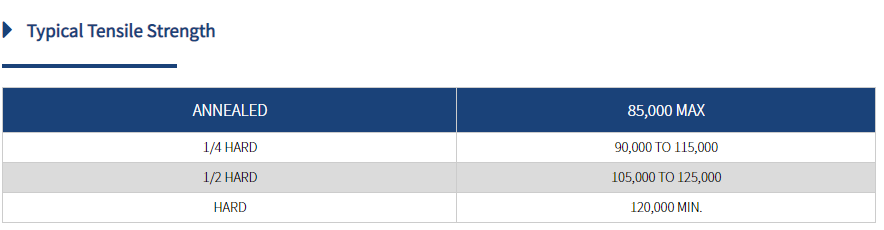

Alloy 46 Mechanical Properties:

Alloy 46 has excellent mechanical properties. It has a tensile strength of 120,000 psi, which is higher than many commonly used alloys, such as carbon steel. Additionally, it has a yield strength of 60,000 psi, making it incredibly durable and resistant to deformation even under high stress conditions.

Alloy 46 uses:

Alloy 46 is commonly used in the aerospace industry to create components with exceptional strength and durability. It produces resistance wire, electronic components and industrial heating elements. It is also a popular choice for marine equipment due to its high corrosion resistance.

Alloy 46 Corrosion Resistance:

The main advantage of Alloy 46 over other materials is its high corrosion resistance. Even in harsh environments, such as those found in the aerospace industry, Alloy 46 remains highly resistant to corrosion, oxidation and erosion. Additionally, its resistance to acidic and alkaline solutions as well as seawater makes it ideal for use in harsh marine environments.

Alloy 46 Heat Treatment:

Alloy 46 was heat treated at 1100°C for eight hours and then water quenched. This process provides excellent tensile strength, making it ideal for industrial applications.

Alloy 46 Processing:

Due to the high strength and hardness of Alloy 46, machining it can be challenging. However, with the proper tools, it can be machined relatively easily. Its high strength means high cutting speeds, and feed rates are a must.

46 alloy welding:

Welding Alloy 46 is a simple process that requires caution. Must be preheated to 175°C before welding. Filler metals whose composition matches the alloy should be used when welding. After welding, it should be tempered at 1100°C for 4 hours and then furnace cooled to ensure optimal strength.

in conclusion:

Alloy 46 is a superior material with exceptional strength, durability and corrosion resistance. Its mechanical and physical properties make it ideal for a variety of applications in various industries. Its corrosion resistance combined with other excellent properties makes it a popular choice for components in aerospace, electrical, industrial and marine applications. If you’re looking for a strong, reliable and versatile material for your next project, look no further than Alloy 46.

Tianjin Anton Metal Manufacture Co., Ltd. is a company specializing in the production of various nickel-based alloys, Hastelloy alloys and high-temperature alloy materials. The company was established in 1989 with a registered capital of 10.0 million, specializing in the production and sales of alloy materials. Anton Metal’s products are widely used in aerospace, chemical industry, electric power, automobile, nuclear energy and other fields, and can also provide customized alloy material solutions according to customer needs. If you need to know the price consultation of alloy materials or provide customized alloy material solutions, please feel free to contact the sales staff.

==========================================

www.antonmetal.com

ANTON METAL| Your specialty alloys manufacturer

Email: dominic@antonmetal.com

Phone: +8613132148618(wechat/whatsapp)

Post time: Mar-01-2024